Waterproof Materials for Bags: How to Choose the Right Fabric for Your Product Line

If you sell bags or plan a new product line, “waterproof” is probably one of the first words your customers type into a search bar. But turning that simple request into the right waterproof materials for bags is a bit more complex. Different coatings, base fabrics and constructions feel similar at first touch, yet they behave very differently once your bag hits real life: rain, coffee, sweat, sunscreen, airport belts, you name it.

This guide walks you through how to choose the best waterproof bag material for your products, using examples that fit cosmetic bags, tote bags, crossbody styles, waist bags and small accessories. The goal is simple: help you pick fabrics that match your brand positioning, your price point and the way your customers actually use their bags.

Why Waterproof Materials Matter for Modern Bag Brands

Waterproof is not just a nice-to-have selling point anymore. For many buyers, it is part of basic quality. Think about where your bags go: gym lockers, bathroom counters, wet café tables, rainy sidewalks. If the fabric soaks through easily, you do not just disappoint the buyer; you also lose repeat orders and reviews.

From a brand angle, the right waterproof fabric for bags also supports:

- Fewer returns from stains and water damage

- Stronger product pages (“keeps your makeup dry even in a downpour”)

- Clearer positioning if you sell travel, outdoor or sports-related bags

At the same time, not every bag needs hardcore dry-bag performance. A party clutch and a bike saddle bag do not need the same waterproof materials for bags, so you can choose smarter instead of always going for the thickest, stiffest fabric.

Key Factors When You Choose Waterproof Bag Material

Before looking at specific fabrics, it helps to decide what “waterproof” actually means for your line.

How Will Customers Use the Bag?

A few simple questions can narrow things down:

- Is the bag meant for daily city use, beach trips, travel, or outdoor sports?

- Do people carry electronics inside, or mostly makeup and small things?

- Will the bag see heavy rain, or just the occasional splash in a bathroom sink?

A small everyday tote might only need water resistant fabric for bags, while a travel wash bag that sits next to a sink all day benefits from a tougher laminated waterproof fabric.

What Do You Need From the Fabric Itself?

For bags, you usually balance four things:

- Hand feel and look (shiny, matte, stiff, soft)

- Strength and tear resistance

- Weight of the material

- Level of water protection

Sometimes you accept a less “luxury” hand feel if you want a strong outdoor look. Other times you want soft, PU-coated fabrics that feel nicer in the hand.

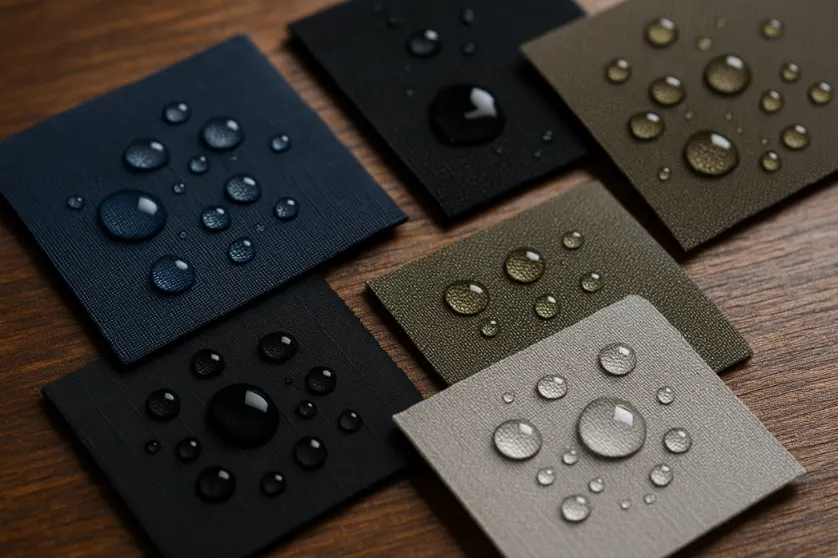

Common Waterproof Fabrics for Bags: A Practical Comparison

Below is a simple comparison of some of the most common waterproof materials for bags you will see in custom production.

|

Fabric Type |

Typical Use Cases |

Main Pros |

Watch Outs |

|

Nylon waterproof fabric |

Backpacks, sports bags, travel cosmetic bags |

Strong, light, dries fast |

Can look very “sporty” |

|

Polyester waterproof fabric |

Totes, promo bags, laptop sleeves |

Color holds well, good price range |

Slightly less strong than nylon |

|

PU-coated fabric |

Cosmetic bags, fashion crossbody bags |

Soft hand feel, semi-matte look, easy to print |

Heat and sunlight over long term |

|

PVC-coated fabric |

Clear bags, beach bags, toiletry bags |

Very good water barrier, easy to wipe clean |

Stiffer, more plasticky feel |

|

Laminated waterproof fabric |

Outdoor totes, diaper bags, lunch bags |

Strong barrier, easy to wipe inside and out |

Can feel a bit rigid if too thick |

|

Canvas with coating |

Casual totes, eco-style bags |

Natural look with added protection |

Needs good coating quality |

You do not have to use all of them. Many brands pick two or three main waterproof bag material options and build most of their line around those.

Matching Materials to Different Bag Types

Every bag category behaves differently on the shelf and in real life. If you mix your designs across several lines, it helps to pick fabrics for each use case.

Cosmetic and Toiletry Bags

These bags live in bathrooms. Water, steam, spilled skincare and perfume are normal. For this category, custom waterproof bags often use:

- Nylon waterproof fabricfor the outer shell

- Laminated waterproof fabricor coated polyester lining inside

- Smooth PU for a more fashion-forward look

A buyer may not know the exact fabric name, but they will feel whether the bag wipes clean and dries fast after a spill.

Tote Bags and Everyday Carry

Totes and everyday bags spend time outdoors, in offices and on public transport. They touch floors and car seats, but they also act as fashion pieces. For this group, common picks include:

- Polyester waterproof fabricwith printing for branding

- Coated canvas for a more casual, natural look

- Lighter PU or nylon for packs that fold down into small spaces

If you plan bulk waterproof bags for promotions or retail, polyester is a popular choice because of its balance between cost, print quality and performance.

Travel and Outdoor Bags

Travel, sports and outdoor bags face more serious rain, dirt and abrasion. Buyers here care more about performance than a gloss finish. Good options:

- Heavier nylon waterproof fabricwith ripstop or Oxford weave

- Laminated waterproof fabricfor panels that touch the ground or sit on wet surfaces

- Strong zippers and seam construction to match the fabric level

In this segment, a small story such as “kept dry in three days of off-and-on rain” can sell better than any technical number.

How a Custom Bag Manufacturer Can Help You Choose

If you do not want to build your own fabric lab, working with a custom bag manufacturer is the realistic route. A good partner will already source from multiple waterproof fabric suppliers, test materials in real production and see how they age over time.

For growing brands, a factory that can act as both OEM bag supplier and private label bag manufacturer is especially helpful. You can:

- Start with small runs using existing materials and patterns

- Test new colors or finishes on proven waterproof materials for bags

- Later move into fully custom shapes once you know what sells

Chic offers custom cosmetic bags, tote bags, crossbody bags, waist bags, purse wallets and various bag accessories such as chains, tags and straps. You choose from PU leather, nylon, canvas, PVC and more, then add your logo, label and packaging style. That way, the same waterproof fabric for bags can support several SKUs across your line, instead of starting from zero each time.

A Simple Process to Select Fabrics for Your Product Line

To make this more concrete, here is a step-by-step way you can use when planning a new season or a new bag collection.

Step 1: Define Use Scenarios

List your key bag types and where they will be used:

- “Urban work tote, light rain, big laptop”

- “Carry-on cosmetic bag, lots of liquids”

- “Weekend gym bag, humid locker room”

This helps decide whether you need water resistant, “shower proof” or nearly fully waterproof.

Step 2: Shortlist 2–3 Core Fabrics

Pick a small set of base fabrics, such as:

- Nylon waterproof fabricfor sporty or travel items

- Polyester waterproof fabricfor printed totes and mid-price bags

- Laminated waterproof fabricfor linings, lunch bags or baby-related items

Using fewer base fabrics makes it easier to manage quality and color consistency.

Step 3: Order Samples and Real-Life Test

Instead of only checking lab reports, you can:

- Pour water and coffee on sample panels

- Wipe them with tissues and rough paper towels

- Put them in a bathroom overnight and see if any edges curl or change

This kind of simple test sometimes tells you more than a long spec sheet.

Step 4: Match Fabrics With Your Brand Story

Some brands want shiny, high-fashion looks. Others want low-key, eco-style bags. You can use waterproof bag material that matches those stories:

- Matte PU or coated canvas for a softer fashion feel

- Clear PVC panels for travel and security checkpoints

- Recycled polyester for eco-positioned lines, if available from your supplier

Brief Introduction to Chic

Chic is a bag and bag accessories manufacturer based in Yiwu, focusing on custom production for brands, wholesalers and importers who sell into Europe, America and many other markets. The company works with PU leather, nylon, canvas, PVC and several other materials, including coated options suitable for custom waterproof bags.

The team supports both OEM and ODM projects, from style development and sampling to bulk production and packaging. With a factory-scale monthly output and a service team used to working with overseas buyers, Chic is set up for bulk waterproof bags as well as smaller runs for new projects. If you want one partner to handle cosmetic bags, totes, crossbody bags and matching bag accessories under one roof, Chic is a realistic option to consider.

Conclusion

Choosing waterproof materials for bags is less about chasing the most technical fabric and more about finding what fits your customers, your price band and your story. Nylon and polyester dominate many lines because they balance price and performance, but coated canvas, PU and laminated waterproof fabric all have their place. The key is to think in use cases, not just in fabric names.

If you work with a reliable custom bag manufacturer, you do not need to guess. You can test a few materials, watch how samples behave, then lock in a small group of fabrics that support your whole product line. Over time, this helps your brand feel consistent and makes it easier for your customers to trust that when a product page says “waterproof,” the bag actually behaves that way in the real world.

FAQ

Q1: What is the best waterproof material for bags?

A: It depends on your product line. For everyday totes and fashion backpacks, coated polyester or nylon is usually enough. For outdoor or travel bags, thicker waterproof fabric for bags like TPU-laminated nylon or PVC works better.

Q2: How do you judge if a fabric is really waterproof?

A: Look at the coating and test data, not just the name. Ask for hydrostatic head (water column) values, check if seams can be taped, and do a simple water splash test on a sample. Truly waterproof materials for bags should block water under pressure, not only light rain.

Q3: Are coated fabrics good enough for brand bags?

A: For most fashion and promotional bags, yes. PU-coated polyester or nylon gives a clean look, good print surface and basic water protection. If your buyers use the bags in heavy rain or near water, then you may upgrade to technical waterproof bag material such as TPU or PVC.

Q4: How should you pick fabric for different bag types?

A: Think by use case. Laptop bags need water-repellent fabric plus padding. Travel duffels need tougher waterproof materials for bags and strong backing. Gift bags or retail packaging can use lighter coated fabric because style and branding matter more than full storm protection.

Q5: Can Chic help choose waterproof fabric for custom designs?

A: Yes. Chic works with many types of waterproof bag material and can match fabric weight, coating and color to your target customers, whether you sell fashion totes, corporate gifts or outdoor gear.