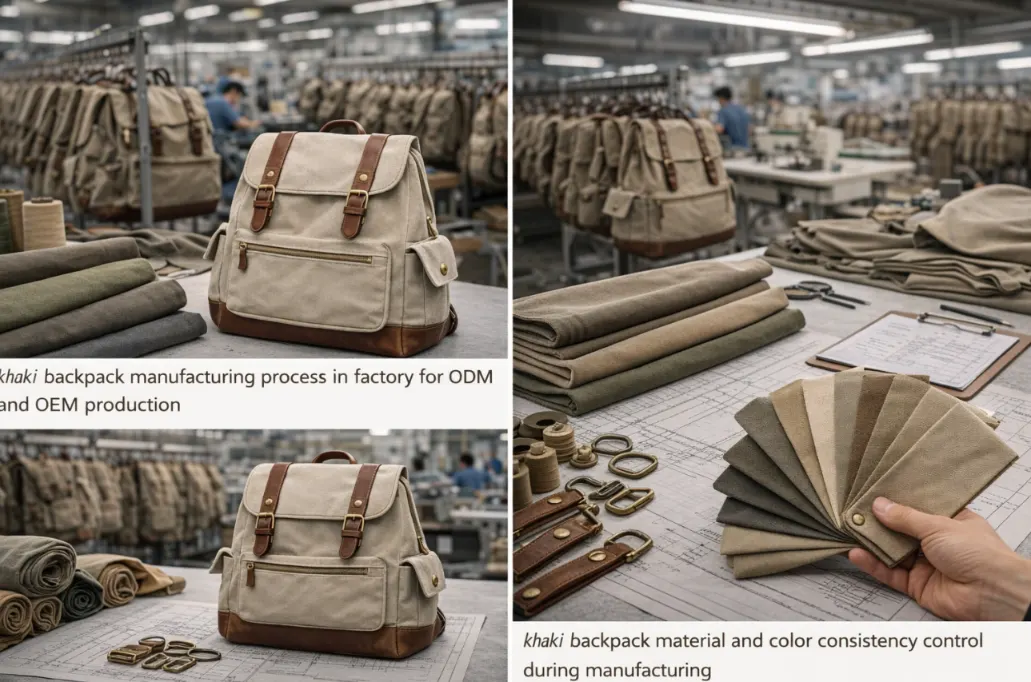

Khaki Backpack Manufacturing: ODM and OEM Considerations for Brands

A khaki backpack looks like a simple choice on a product board, but it becomes a high-impact manufacturing decision once you plan repeat orders. For many brands, khaki is not a seasonal color. It is a core SKU that needs stable shade, consistent trims, and predictable lead times across multiple purchase cycles. That is why khaki backpack manufacturing is less about “picking a color” and more about choosing the right production approach, whether you rely on khaki backpack ODM, khaki backpack OEM, or a practical mix of both.

Why Khaki Backpacks Are Often Chosen as Core SKUs

Brands often treat a khaki backpack as a safe anchor color because it travels well across markets, seasons, and use cases. In women’s bag lines, khaki can sit between black and beige, offering a neutral that feels softer than black but more durable-looking than light tones. From an operations view, the bigger advantage is that khaki supports a core-SKU strategy: you can test demand with a limited run, then scale into bulk khaki backpacks with fewer merchandising changes than a trend color would require.

That core-SKU role is exactly why you should be stricter with supplier selection. A one-time fashion color can tolerate small shade variation. A core khaki cannot. If your shade shifts between POs, customers notice it in photos, retailers complain about inconsistency, and your internal inventory gets harder to manage.

Material and Color Control in Khaki Backpack Manufacturing

When you speak with a khaki backpack manufacturer, the key question is not “Can you make khaki?” The real question is “Can you make my khaki the same way next quarter?” Shade stability depends on both fabric and process, and khaki is especially sensitive because small shifts read as “greenish,” “yellowish,” or “muddy” depending on lighting.

Fabric Selection and Shade Consistency

Khaki does not look identical across materials. Canvas, twill, nylon, and blended fabrics each reflect light differently, and coatings can change the perceived tone. If you want a custom khaki backpack, align early on:

-

Fabric type and weight range (shape retention vs softness)

-

Surface finish (matte vs slightly sheeny)

-

Lining color, because it can influence the overall look in photos and retail displays

In women’s backpack manufacturing, you also need to decide whether khaki is a “system color” across multiple SKUs. If your plan includes a matching tote, mini backpack, or pouch, you will want fabric sourcing that can support consistent khaki across formats—not just a single bag body.

Dyeing, Finishing, and Batch Stability

Color issues are often created after you approve the first sample. Dye lots, finishing steps, and even hardware plating can introduce drift. A capable khaki backpack factory should be able to describe how they manage:

-

Color standards (physical swatch or agreed lab standard)

-

Lot separation and tracking in the production line

-

What happens when a fabric batch is slightly off (re-dye, re-order, or downgrade)

If a supplier cannot explain their bag manufacturing process for color consistency, treat that as a risk signal. For private label khaki backpack programs, consistent shade is part of your brand identity, not a “nice to have.”

ODM vs OEM Considerations in Khaki Backpack Projects

For brands, the ODM vs OEM decision is rarely absolute. Many successful programs start with ODM to move faster, then switch to a tighter OEM structure for long-term repeatability.

When Khaki Backpack ODM Makes Sense

Khaki backpack ODM approach can be useful when you want speed and you are launching a category for the first time. ODM can help you start with a proven pattern and a stable construction method, then adjust details—pocket layout, strap style, trims, or branding—without a long development cycle. That is especially helpful if khaki is one of several launch colors and you need market feedback before committing deeply.

When Khaki Backpack OEM Is the Better Fit

Khaki backpack OEM approach becomes valuable when khaki is confirmed as a core seller and you want tighter control over every variable: fabric vendor, finishing steps, stitching standards, and packaging. OEM workflows tend to be clearer for long-term repeat orders because you lock specifications and reduce “interpretation” by different teams over time. If you plan ongoing replenishment, an OEM-style spec discipline often reduces color drift and detail variance.

The Common Hybrid Model Brands Use

A practical approach is to begin with a strong base from ODM, then transition to OEM-level documentation once the product is validated. This hybrid model can keep your launch quick while protecting consistency when you scale bulk khaki backpacks.

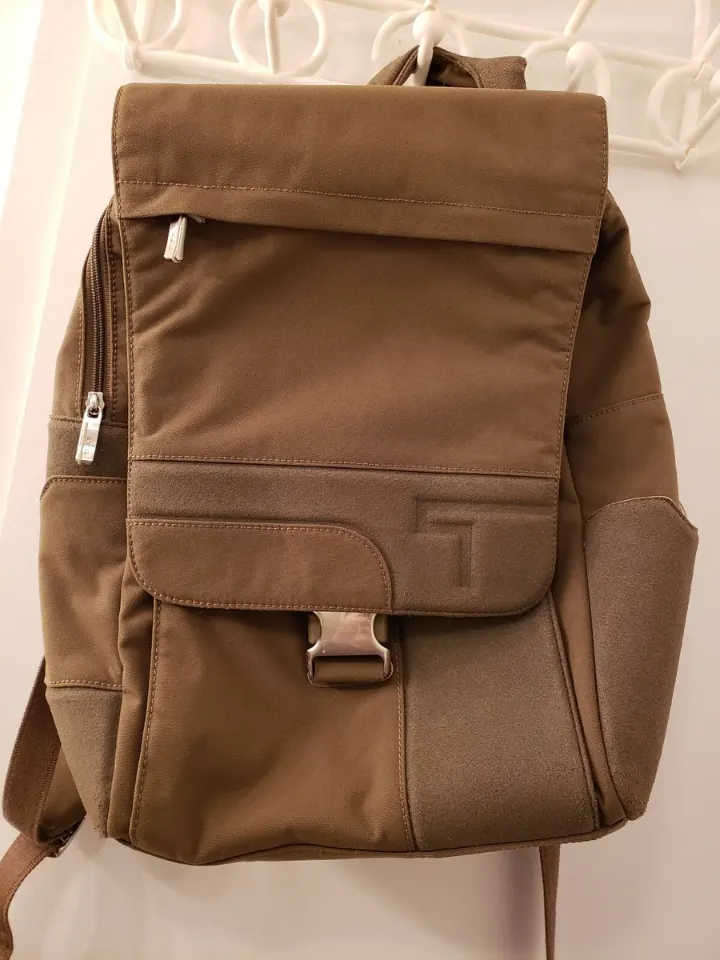

Hardware and Detail Matching for Khaki Backpacks

Khaki makes details more visible. Black hardware on khaki can feel tactical. Brass can feel vintage. Matte nickel can feel modern. But even when you choose a direction, consistency matters. In khaki backpack manufacturing, brands often face issues like:

-

“Same zipper” from different suppliers looking slightly different

-

Webbing shade not matching the body fabric

-

Leather patch or trim reading warmer or cooler than the main khaki tone

For a custom khaki backpack manufacturer, detail control is part of color control. Ask how they align trim color standards with the main fabric, and whether they can keep the same hardware supplier across repeat orders. If your program is private label khaki backpacks for retail, these small mismatches can become costly because they show up in customer photos and returns.

MOQ and Production Planning for Khaki Backpack Orders

MOQ is not one number. It is a set of minimums tied to fabric, color, and accessories. A reliable khaki backpack manufacturer should break MOQ down in a way your team can plan around.

Typical MOQ Structures

Common MOQ drivers include:

-

Fabric MOQ (often the biggest lever for shade consistency)

-

Color MOQ, especially if you want multiple khaki variants (light khaki vs olive khaki)

-

Hardware MOQ (custom zipper pulls, branded buckles, logo plates)

-

Packaging MOQ (custom hangtags, polybags, cartons)

If you want custom khaki backpack details, confirm whether the MOQ applies per colorway, per style, or per purchase order. That changes your launch plan and your reorder strategy.

How Khaki Affects Reorders and Inventory Strategy

Khaki is often chosen because it supports replenishment. But replenishment only works if the supplier can maintain shade stability. Brands that plan for long-term reorders usually:

-

Lock a core khaki standard and avoid frequent shade tweaks

-

Combine reorders across related SKUs to optimize fabric purchasing

-

Maintain a consistent supplier relationship to protect repeatability

This is where the backpack supply chain behind your factory matters. A factory can be skilled, but if their upstream material sourcing is unstable, your khaki consistency will suffer.

Common Manufacturing Risks Brands Face with Khaki Backpacks

Most problems are predictable. The common risks include:

-

Sample approval based on one batch, followed by color drift in bulk

-

Fabric substitutions during tight lead times that change khaki’s tone

-

Different interpretations of “khaki” between suppliers and regions

Quality stability issues that appear only at scale: uneven topstitching, strap anchoring variation, pocket alignment drift

A khaki backpack OEM factory or ODM partner that treats documentation casually will usually create these issues. Your goal is to build a manufacturing system that can repeat—not just a sample that looks good once.

How Brands Can Reduce Risk When Manufacturing Khaki Backpacks

If khaki is a core SKU, treat it as a controlled standard. Practical steps that reduce risk:

-

Approve a clear khaki standard and require it for every reorder

-

Align body fabric, webbing, and trims under the same standard

-

Use a structured sampling path that mirrors real production steps

-

Confirm the supplier’s approach to lot tracking and in-line inspection

-

Choose partners who can support long-term women’s backpack manufacturing, not just a one-off run

When you do this, khaki backpack manufacturing becomes a scalable advantage. You are not just shipping a color. You are building a repeatable supply system that protects your brand image across every restock.

Conclusion

A khaki backpack can be one of the most reliable products in a brand’s lineup, but only if your manufacturing approach supports repeatability. Whether you choose khaki backpack ODM, khaki backpack OEM, or a hybrid path, focus on material control, shade stability, hardware matching, and MOQ planning. The brands that win with khaki do not treat it as a simple neutral—they treat it as a core SKU that deserves production-level discipline.

Chic as a Long-Term Manufacturing Partner for Core Backpack SKUs

Chic supports brands and retailers developing scalable bag programs with a focus on consistent execution in real production. For core colors like khaki, Chic emphasizes material selection, shade control across repeat orders, and structured sampling that matches mass manufacturing steps. This practical approach helps brands move from initial launch runs to stable replenishment, while keeping quality and details consistent across growing SKU lines.

FAQ

Q1: How do you avoid color drift in khaki backpack reorders?

A: Lock a clear khaki standard early, track fabric lots, and keep the same material and trim suppliers whenever possible. Reorders should reference the same approved standard, not just a photo.

Q2: Is khaki backpack ODM or khaki backpack OEM better for long-term programs?

A: Many brands start with khaki backpack ODM for speed, then shift toward OEM-style documentation for tighter consistency once the SKU proves demand. A hybrid approach often works best.

Q3: What usually drives MOQ for a custom khaki backpack?

A: Fabric and trim minimums are the main drivers, especially when you add branded hardware or custom packaging. MOQ can vary by colorway, so confirm the structure upfront.

Q4: Why do khaki backpacks show detail issues more than black backpacks?

A: Khaki highlights mismatch. Small differences in webbing shade, hardware plating, or stitching alignment stand out more than they would on darker colors.

Q5: What is the fastest way to make a private label khaki backpack feel unique?

A: Use a stable base construction, then differentiate with a consistent signature: pocket layout, trim direction (brass vs matte), a recognizable patch placement, and a repeatable lining color strategy.